Meticulous

Craftsmanship

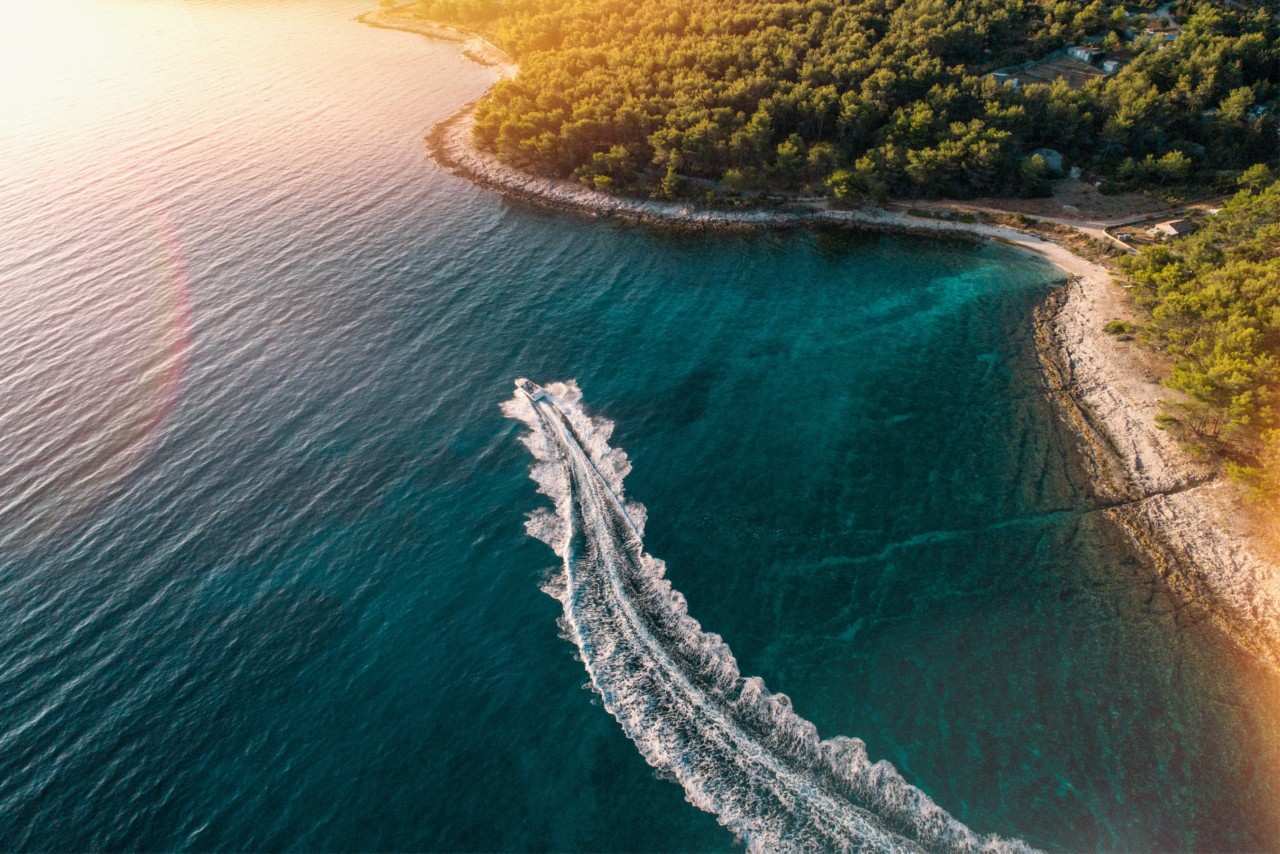

Every Moment Perfectly Crafted

Somewhere in between the items on the long list of life's to-dos, there exists a small sliver of time. Yet it's this part that, while tiny in comparison, takes up the most room in our hearts and memories. At Sea Ray®, we understand how vital this time is to you. How a weekend afternoon with the water stretched out before you is the most rewarding part of your week. It is this understanding that defines everything we do.

What makes a Sea Ray a Sea Ray?

At Sea Ray we believe that richer moments on the water lead to a richer life. We have a strong ideology made up of five basic tenets that guide everything we do. Every Sea Ray® boat and every Sea Ray experience must abide by these principles.

BUY A BOAT WITH CONFIDENCE

Sea Ray’s free digital shopping guide helps you navigate the boat buying process.

Sea Ray's 65th Anniversary

At Sea Ray, we believe that richer moments on the water lead to a richer life. That's why everything we do is designed to make each moment exceptional. What started in 1959 as a small recreational fiberglass boat builder has grown into one of the largest and most well-known pleasure boating companies in the world.

FEELING INSPIRED?

Discover the Sea Ray lineup, find the boat that is just right for you, or use our build-a-boat to further explore options and features.